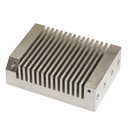

Prototype

CNC Machining prototypes provides our clients with the ability to inspect a real version of their part instead of a SL or SLS simulant. By obtaining a machined prototype from TGI, our clients are able to have the closest match to a production part that they can find before putting their parts into actual production. Our prototypes can even be painted or have texture added so that they match the aestethics of the production specifications.

CNC Machining prototypes provides our clients with the ability to inspect a real version of their part instead of a SL or SLS simulant. By obtaining a machined prototype from TGI, our clients are able to have the closest match to a production part that they can find before putting their parts into actual production. Our prototypes can even be painted or have texture added so that they match the aestethics of the production specifications.

TGI could also use CNC Machining as an accompaniment to other rapid prototyping processes such as SLS, SLA, and FDM. These processes allow our clients to figure out the fit and function of their designed production part. We like to remind our clients that not all prototypes can be completed using these processes, and that many require the use of CNC Machines. Contact TGI to find out more about our prototype machining services, and how we can help you with your production part needs.