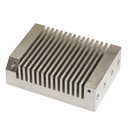

Turning

At TGI we use state of the art programming software to ensure detailed repeatability of production parts and components. Using our computer-automated lathes and machinery, we're able to work with our clients to create a smooth process with unparalleled results. Our CNC turning abilities give us the opportunity to manufacture parts and components from various materials. Our client's needs are put first when determining which machine to use and how to complete the turning process. No step is overlooked, and no product falls out of tolerance.

At TGI we use state of the art programming software to ensure detailed repeatability of production parts and components. Using our computer-automated lathes and machinery, we're able to work with our clients to create a smooth process with unparalleled results. Our CNC turning abilities give us the opportunity to manufacture parts and components from various materials. Our client's needs are put first when determining which machine to use and how to complete the turning process. No step is overlooked, and no product falls out of tolerance.

The turning department at T.G. Industries is equipped to handle even the toughest jobs with speed and accuracy rivaling screw machines. From a simple bushing to a complex flange we can suit your needs. Our turning department consists of five (5) CNC turning centers and three (3) manual lathes. The CNC's consist of a Mori-Seiki SL25A 500, a Feeler FTC 200L, a 2 Daewoo Lynxs, and a Nakamura Tome TMC 15. Also for short run or proto types we have a ProtoTRAK 1630 lathe. Our current turning capacities include up to 2 1/2" dia. bar feeding capability and individual pieces up to 16" dia. and 25" long.

For more information on CNC turning services offered by TGI, please contact us. We're happy to answer any and all questions you may have when it comes to your turning needs.